-

1 Re-inspection of raw materials

After the raw materials enter the factory, the company rechecks the raw materials according to relevant standards to ensure the stable quality of the products at the source.

-

2 Sawing and blanking of raw materials

The sawing area adopts the Austrian Linsinger high-speed circular saw, which has the functions of automatic volume measurement, weighing and other functions. The quality control is accurate, the weigh...

-

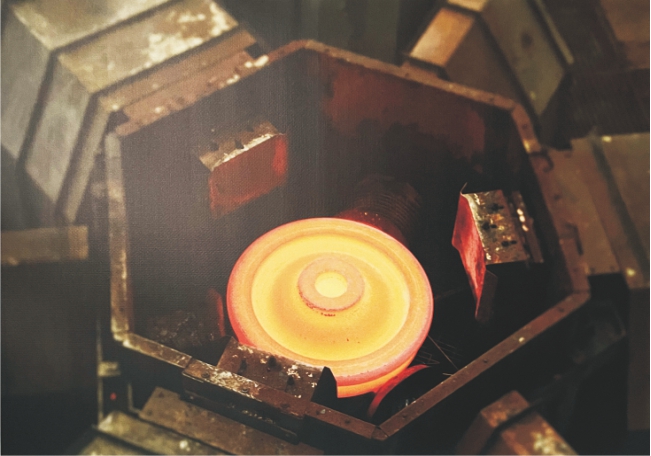

3 Ring furnace heating

The diameter 24M annular heating furnace is fully loaded with 360 pieces of material. It is heated by natural gas, and the temperature uniformity is ± 10 ℃ through pulse proportional temperature contr...

-

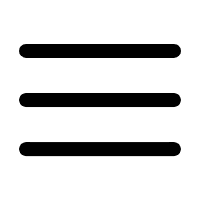

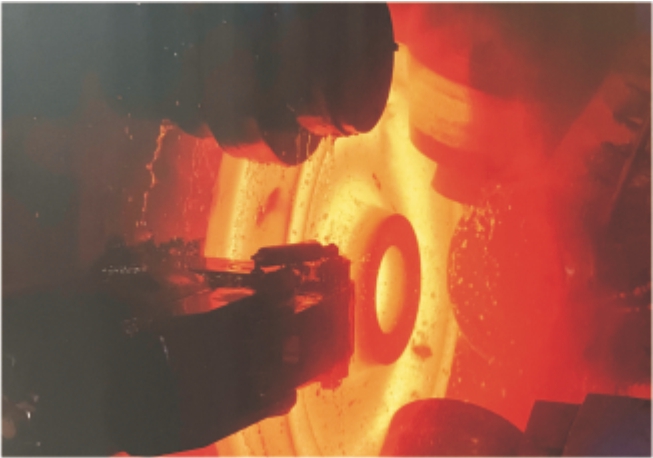

4 Wheel Preform

Wheel pre-forming The wheel pre-forming is completed on a 50MN frame hydraulic press, and the metal is distributed for the first time after being pressed to the height required by the process.

-

5 Wheel forming

Wheel forming The wheel forming is completed on a 100MN frame hydraulic press to realize the second metal distribution of the hub, web and rim.

-

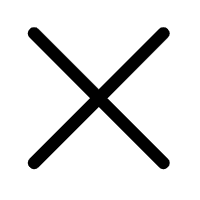

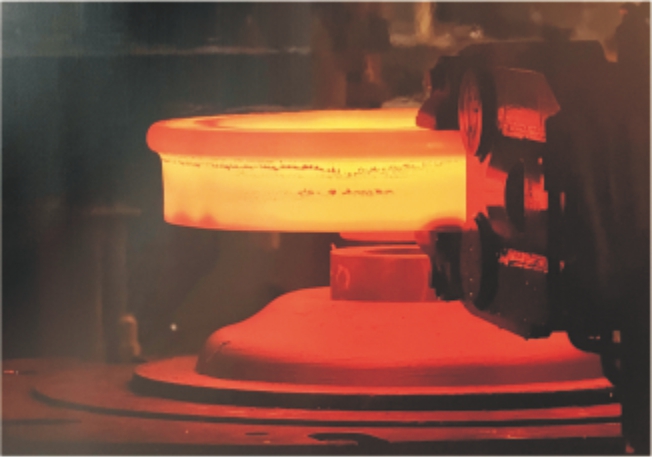

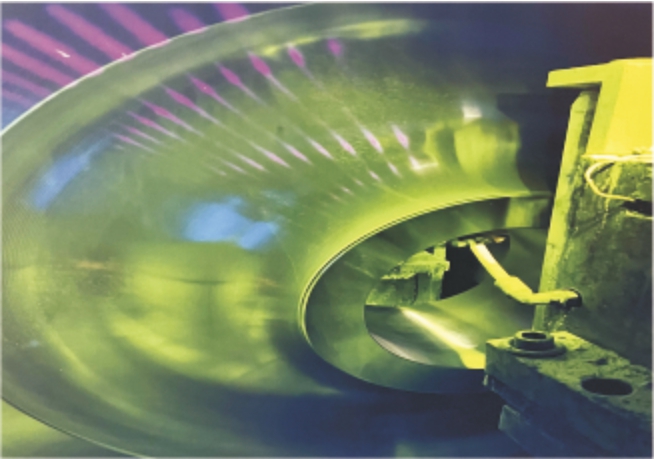

6 Wheel rolling

The formed rear wheel blank is put into the DRAW1250 mill for rolling, so that the web plate, rim, rim and other parts can achieve effective forming results, and the rolling accuracy can achieve ± 1mm...

-

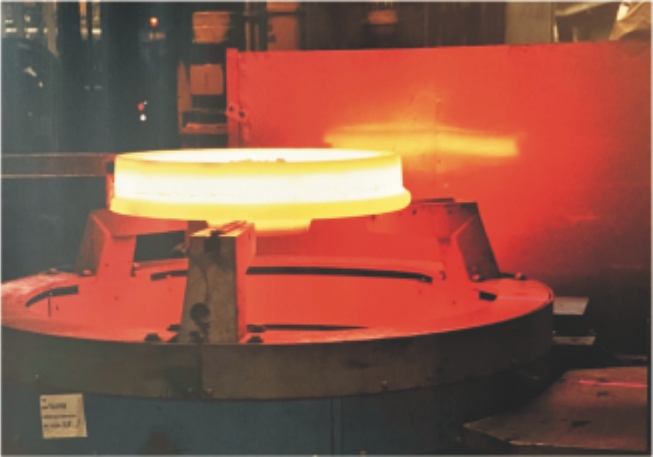

7 Wheel bending and punching

The rolled rear wheel blank is put into a 50MN frame hydraulic press to complete the final forming of the wheel blank web and rim, and the core material is separated from the wheel body through punchi...

-

8 Hot identification printing

Through the information system, the identity information such as the wheel heat number and billet number are engraved on the wheel surface by the hot marking machine to realize the identity informatio...

-

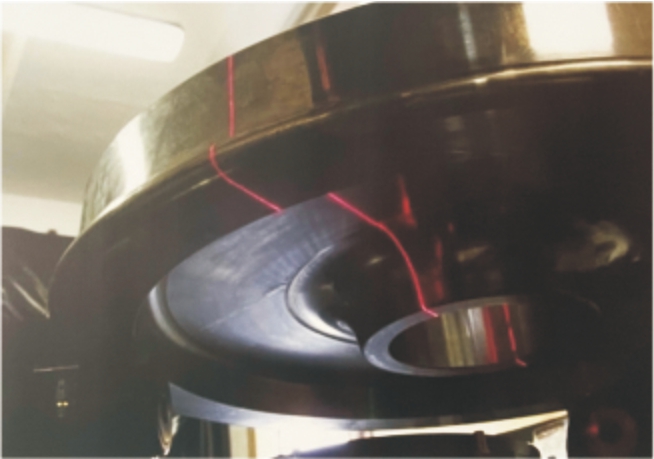

9 Geometric dimension measurement of hot forgings

The forging and rolling line is equipped with thermal 3D laser measuring equipment, which can intuitively and clearly judge the forming quality of the product at 1150 ℃, timely feedback and realize pa...

-

10 Wheel quenching heating

Through the tunnel heating furnace, the wheel annealing, quenching heating and tempering are realized, and the pulse proportional temperature control is used to achieve the temperature uniformity of ±...

-

11 Wheel quenching treatment

The quenching system can automatically control the water temperature, water pressure and water volume, realize the online monitoring of quenching parameters, and effectively guarantee the uniformity, ...

-

12 Turning and machining

The wheel processing adopts the German Hagenset processing and drilling and milling center. Each processing center has its own measuring instrument, which can realize the automatic and independent pro...

-

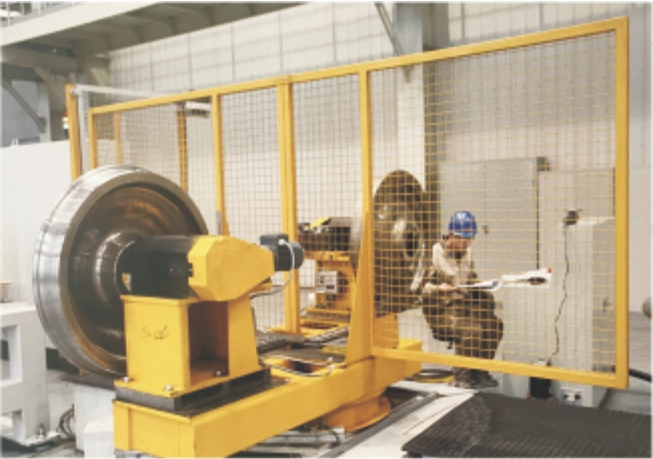

13 Wheel static unbalance detection

The residual static unbalance value of the wheel can be accurately measured by the centrifugal method, which can directly reflect the processing level and ensure the stability of the wheel at high spe...

-

14 Wheel surface hardness test

Carry out Brinell hardness test on the wheel rim surface with a pressure of 3000kg to ensure the wear resistance of the wheel.

-

15 Visual inspection of wheel surface quality

The duplex visual inspection platform can be used to check the wheel surface quality from multiple angles and measure the key and special dimensions.

-

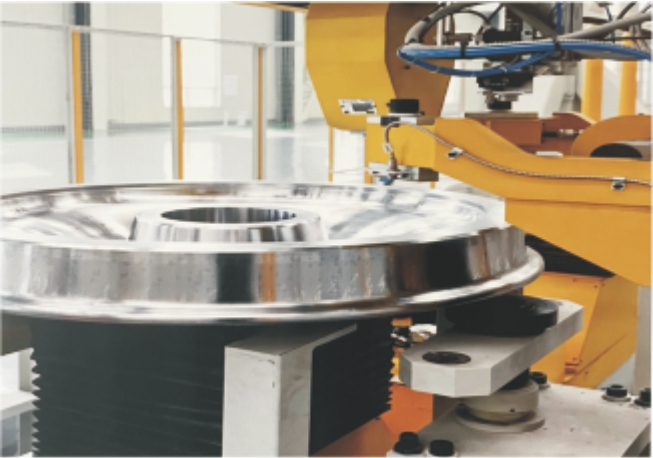

16 Automatic full-size measurement of wheels

The laser three-dimensional measurement method is used to quickly realize the online measurement of wheel geometric dimensions and tolerances, avoiding the interference of human factors, and the measu...

-

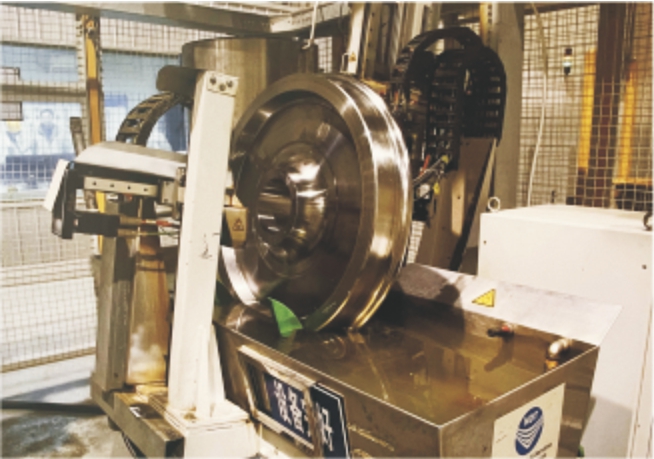

17 Ultrasonic inspection of wheel internal defects

Using the water immersion phased array ultrasonic testing technology, it can detect the internal defects of the wheel with high accuracy, save the blind area and quickly, and eliminate the hidden dang...

-

18 Magnetic particle testing of wheel surface defects

Fluorescent wet magnetic particle inspection of wheel surface and near-surface defects can intuitively find defects that are not easy to find with the naked eye under normal conditions, and ensure whe...

-

19 Finished product packaging and shipping

In order to ensure the traceability of the product, the serial number that can identify its identity can be engraved on the surface of the product wheel. After the wheel is delivered to the customer, ...

-

20 Finished product packaging and shipping

Automatic intelligent subcontracting system is adopted, which can complete automatic classification and destacking of wheels according to preset conditions. The whole inspection line is run through th...